When it comes to wastewater treatment, having a solid Sludge Management System is a game-changer. It really helps improve how smoothly operations run and also cuts down on environmental harm. I recently came across a report from the Global Sludge Management Market, and it mentioned that the need for cutting-edge sludge treatment tech is expected to hit around $25 billion by 2027. That’s mainly because stricter regulations and a push for sustainability are pushing industries to get creative with how they handle sludge. Companies are definitely looking for better alternatives to the old-school methods, and

APEX Company is leading the charge.

They offer top-of-the-line sludge drying and conveying equipment, especially tackling those tricky wastewater issues. If you ask me, APEX has really made a name for itself, not just in China but worldwide, earning the trust and praise of many clients. Using these advanced sludge management methods doesn’t just make waste treatment more efficient, but it also helps move us toward a greener future. All in all, embracing smarter Sludge Management Systems really makes a difference.

They offer top-of-the-line sludge drying and conveying equipment, especially tackling those tricky wastewater issues. If you ask me, APEX has really made a name for itself, not just in China but worldwide, earning the trust and praise of many clients. Using these advanced sludge management methods doesn’t just make waste treatment more efficient, but it also helps move us toward a greener future. All in all, embracing smarter Sludge Management Systems really makes a difference.

Managing sludge properly is such a crucial part of wastewater treatment. You see, as the water gets cleaned, all the solid waste stuff tends to pile up, turning into sludge. If we don’t handle it right, it can cause quite a few headaches. That’s why good sludge management is a big deal — it helps protect the environment, allows us to recover resources, and keeps everything in line with the rules. Plus, when we handle sludge efficiently, we not only reduce the risks tied to untreated waste, but we also have the chance to reclaim some pretty valuable goodies like biogas and fertilizers.

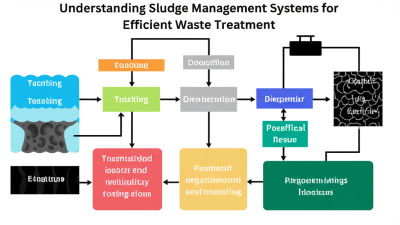

On top of that, getting the sludge part right is key to making the whole treatment plant work better. By using advanced methods—think anaerobic digestion, thickening, and dewatering—plants can cut down on how much sludge they generate. This means lower disposal costs and smoother operations overall. Adopting innovative strategies for sludge management not only boosts sustainability but also helps organizations do a better job of meeting environmental standards. Long story short, investing in a solid sludge management system is really the way to go if you want your wastewater treatment process to be effective and long-lasting.

| Parameter | Value | Unit |

|---|---|---|

| Sludge Volume | 1000 | m³/day |

| Dry Solids Content | 20 | % |

| Organic Matter Reduction | 90 | % |

| Energy Recovery Efficiency | 60 | % |

| Biogas Production | 200 | m³/day |

| Dewatering Rate | 5 | %/min |

| Sludge Disposal Cost | 150 | $/ton |

| Carbon Footprint Reduction | 30 | % |

Effective sludge management is a huge deal in the waste treatment world—especially for industries trying to boost their efficiency and stay on the right side of environmental rules. You know, the main parts of these systems usually include thickening, dewatering, and stabilization tech, to keep things running smoothly. I recently came across a study from the Water Environment Federation that mentioned using advanced dewatering techniques can cut down sludge volume by as much as 90%. That’s a game changer because it means way lower disposal costs and less mess in landfills.

At APEX Company, we’re really proud to be leading the charge with innovative solutions. We've got top-notch sludge drying and conveying equipment that help streamline the whole process. Our wastewater treatment options are designed for those who really want to do things sustainably. Plus, industry reports are showing that the global market for sludge treatment tech is growing by about 5.5% every year—that’s pretty encouraging! Our gear has earned a lot of trust from customers both in China and around the globe, proving just how essential solid, reliable sludge management systems are in today’s environmental scene.

You know, in recent years, the world of sludge management has really come a long way. Thanks to some pretty exciting tech innovations, treatment has gotten a lot more efficient. Stuff like anaerobic digestion and fancy dewatering methods are totally changing how we deal with wastewater — now we're turning sludge into useful resources instead of just tossing it out. These new tools don’t just cut down on the amount of sludge; they also pull out energy and nutrients that can be used in farming or to generate power.

By the way, one tip worth considering is adding real-time monitoring systems into your processes. They can give you on-the-spot data about how things are running and help spot spots that might need a little tweaking. Basically, it helps keep everything operating smoothly and at its best.

Plus, amazing innovations like membrane bioreactors (MBRs) and biopolymer additives are making it so much easier to separate and recycle water from sludge. MBRs improve filtration and take up less space, while biopolymers help with thickening and dewatering. Jumping on these cutting-edge solutions not only lowers your environmental impact but can also save you some serious costs in the long run.

Oh, and don’t forget — keeping your team in the loop is super important. Regular training sessions or workshops on the latest sludge treatment tech can really boost how effective your operations are. Plus, when everyone’s up-to-date on new trends, you’re way more proactive about managing waste overall.

Good sludge management really plays a huge role in making waste treatment sustainable, but it’s all heavily shaped by the regulations in place. In many parts of the world, strict rules are set up to make sure sludge is disposed of safely and, whenever possible, turned back into useful stuff. I read in the 2021 UN-Habitat Global Waste Management Outlook report that around 2.01 billion tonnes of municipal waste are produced each year, and a good chunk of that is sludge from wastewater treatment. That really shows why having comprehensive regulations is so crucial—not just to protect the environment, but also to encourage technologies that turn waste into resources.

Plus, these rules often promote the idea of the circular economy, pushing for the recovery of valuable materials from sludge. Take the European Union’s Waste Directive, for example — it has pretty bold recycling goals, aiming for at least 65% of municipal waste to be recycled by 2035. These kinds of regulations spark innovation, like using anaerobic digestion or thermal treatments to convert waste into energy or even organic fertilizers. Interestingly, a recent report from the International Water Association mentioned that up to 80% of the nutrients in wastewater could actually be recovered with advanced sludge management techniques. That’s a win-win — it helps support sustainable farming and cuts down on the amount going to landfills.

Managing sludge effectively is pretty important if we want to cut down on the economic hits that come with sewage treatment. I came across this recent study from Wuhan, China, where they looked into six different local sewage treatment options. The findings were pretty eye-opening—there were big differences in how much greenhouse gases they produced and how much energy they used. For instance, incinerating sludge, which is really key for safely disposing of waste and even recovering resources, was also seen as a way to ease the financial burden since it can generate energy back. Pretty cool, right?

On another note, there was this study in Austria about recycling phosphorus—kind of a big deal in sustainable waste management. The analysis showed that putting effort into recycling not only helps save money on disposing of waste but also turns what would be trash into something valuable, giving local economies a boost. As cities move more toward a circular economy, bringing in advanced tech like Fenton-based processes is becoming super important. These methods can boost what traditional sludge management can do, helping the environment and saving costs at the same time. All in all, it’s clear that embracing innovative practices is the way to go if we want to keep waste treatment both eco-friendly and economically sustainable.

Managing sludge effectively is a real key to making waste treatment better and getting the most out of resources. Honestly, using the right strategies in sludge treatment can really boost how well wastewater plants perform. A big part of this is using advanced anaerobic digestion — it not only shrinks the amount of sludge but also turns it into biogas, which can be used as a renewable energy source. Plus, bringing in new tech like membrane bioreactors and thermal hydrolysis can also improve the quality of the sludge, turning it into something useful for farms or industry.

On top of that, keeping a close eye on what’s in that sludge through regular tests and monitoring is super important. With real-time data, facilities can tweak their processes to better remove contaminants and recover nutrients. Techniques like centrifugation or belt filter presses for dewatering help cut down on transportation costs and energy use, making everything more eco-friendly and cost-effective. So, taking a kind of all-in approach—using smart tech, real-time insights, and a focus on resource recovery—can really take sludge management to the next level, with big environmental and economic wins.

: Sludge management is important because it minimizes environmental impact, promotes resource recovery, and ensures compliance with regulatory standards, while also mitigating risks associated with untreated waste.

Key components include thickening, dewatering, and stabilization technologies, which collectively enhance operational efficiency and environmental compliance.

Advanced dewatering techniques can reduce sludge volume by up to 90%, significantly lowering disposal costs and reducing landfill impact.

Effective sludge management strategies can minimize economic burdens by reducing greenhouse gas emissions, energy consumption, and disposal costs, while also supporting resource recovery.

Technologies such as anaerobic digestion, thickening, dewatering, and Fenton-based processes are essential for optimizing sludge management and enhancing sustainability.

Sludge incineration facilitates safe disposal and resource recovery and is identified as a method that can alleviate the economic burden of sludge management due to its energy recovery potential.

Sustainable recycling strategies reduce disposal costs and turn waste into valuable resources, helping to support local economies and move towards circular economy principles.

Municipalities can improve practices by integrating advanced technologies and innovative processes to enhance traditional sludge management systems, improving both environmental performance and cost efficiency.

When it comes to wastewater treatment, having reliable sludge management systems is a game-changer. They’re not just about making the process more effective; they also play a big role in helping us take care of the environment. A solid system usually features key stuff like advanced drying and conveying equipment—these parts make sure sludge gets handled smoothly and consistently. Thanks to ongoing tech innovations, sludge treatment keeps getting better and more efficient. Plus, strong rules and regulations ensure everything’s disposed of properly and resources are recovered responsibly. And let’s not forget, from an economic standpoint, good sludge management isn’t just about being green; it’s also about saving money and making solutions more affordable, which is a win-win.

At APEX Company, we’re really proud of what we do. We provide top-quality drying and conveying equipment that’s designed to meet the growing worldwide demand for effective wastewater treatment solutions. Our focus on building high-end, tough-to-make equipment has earned us trust and praise from customers around the globe. We’ve managed to position ourselves as leaders in the sludge management field by blending best practices with the latest technology. Ultimately, our goal is to help our clients achieve the best possible sludge treatment results—because a cleaner environment’s good for everyone, right?